An additional area of expertise in the sea and shore construction path is our helical equipment support. Using helical products in seawall and bulkhead projects allows for efficient projects and most importantly safe structures.

Connect with one of our Professional Engineers for guided support and helical solutions in your sea and shore construction projects.

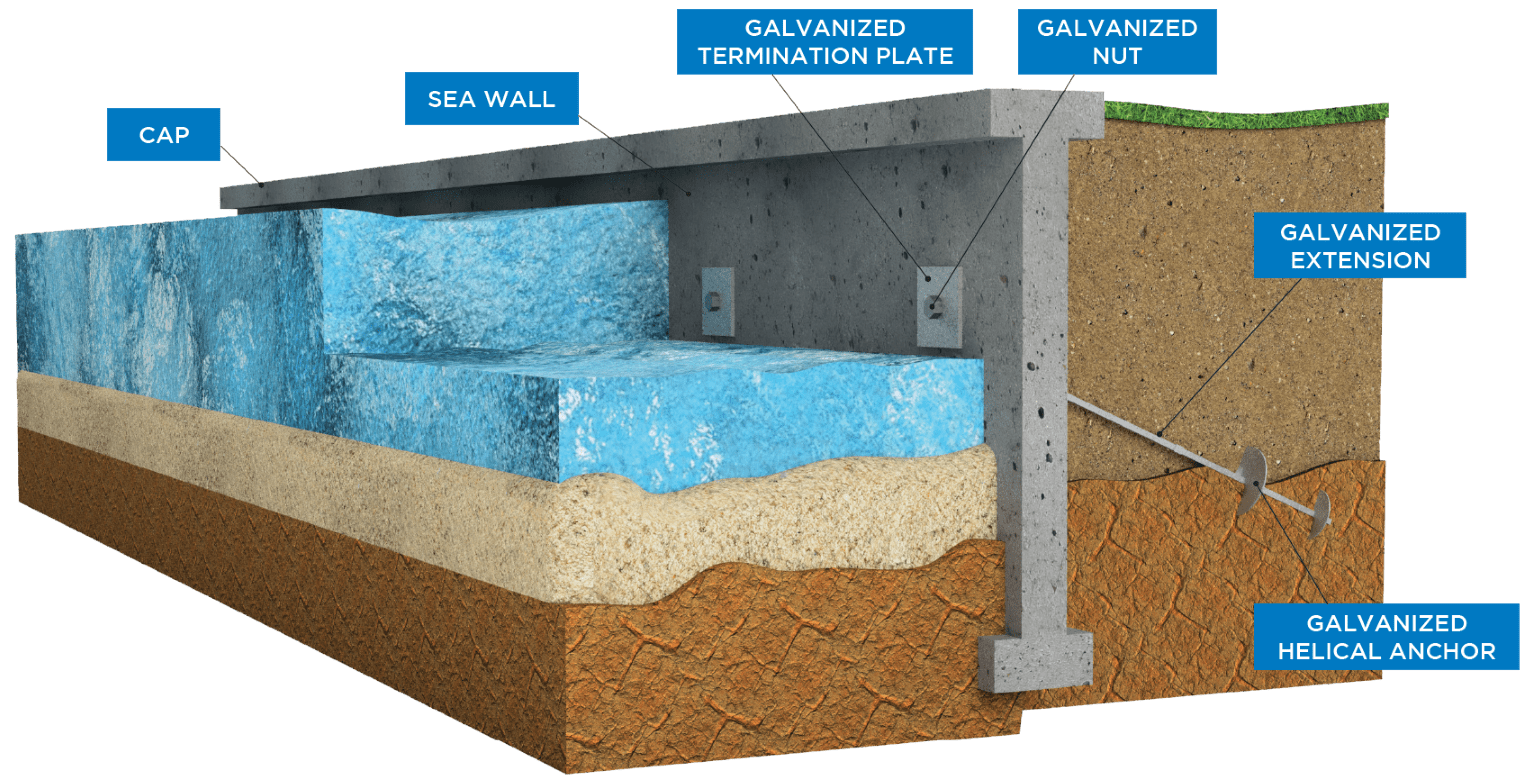

Helical tieback anchors are a type of foundation support system that uses a steel shaft with helical plates to transfer lateral loads from the foundation to the surrounding soil. They can be installed without excavation, making them a cost-effective solution for repairing existing seawalls or constructing new ones.

The use of helical tieback anchors in seawall and bulkhead construction has proved to provide excellent lateral support and stability, and they are often used in conjunction with other support systems, such as sheet piles or concrete walls, to provide additional reinforcement.

Helical tiebacks offer additional advantages over conventional deadmen methods. The elimination of exaction, quick install, and creating tension, immediately saves time and money, especially in locations where excavation is difficult or impossible.

Plus, helical tieback anchors are classified as soil anchors and the loads are developed based on the capacity of the soil behind the wall. The holding capacity is proportional to the installation torque of each anchor. The length and bearing area can be adjusted in the field to meet the specified load requirements for the project.

Because each seawall and bulkhead project is unique, our professional engineers and team of experts are available to assist throughout the entire process, from design to completion.

In the domain of residential construction, particularly in areas adjacent to bodies of water, it is critical to choose proper installation equipment for seawall projects. Due to the variety of seawall applications – concise engineering is key for all seawall design and builds.

Seawall Applications: Ideal for properties fronting beaches or coastlines that are directly exposed to the ocean and thus prone to storm surges, pounding surf, and severe shoreline erosion. Seawalls are crucial in these settings to both protect the shore from wave damage and to retain soil behind the structure.

Partner with us for guided support from our Professional Engineers for your seawall installation equipment.

Tim is the President of Intech Anchoring and has 25 years of experience in the Civil Engineering and Geostructural Industry. Tim has developed extensive industry knowledge by working to support the needs of specialty contractors at each and every business level. Tim’s diverse industry background has given him exposure to a wide variety civil construction projects, ranging from the simplest residential applications to the most complex commercial and industrial projects. Coupled with a highly skilled and educated team, Tim focuses on providing the highest quality products and solutions to Intech Anchoring’s customers in order to consistently exceed expectations.