SCAN FOR MOBILE VIEW

This TIP is intended to facilitate the process of a Mud Balance test. A Mud Balance test is used to find the specific gravity (SG) for the grout mixture. This is done by comparing the unit weight of the grout mixture to the unit weight of water.

Generally, the industry works within a 1.80 to 1.90 SG for structural grout. For example, five gallons of water mixed with a typical 94 lb. bag of type II Portland cement will give a specific gravity around 1.84, which typically corresponds to a 7-day compressive strength of 5,000 psi. These numbers will vary based on your unique job site and soil types.

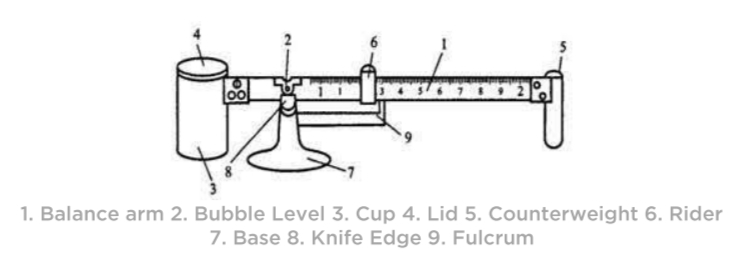

Calculating the unit weight of grout can be easily done with a grout volume calculator or a Mud Balance Testing Scale.

Tim is the President of Intech Anchoring and has 25 years of experience in the Civil Engineering and Geostructural Industry. Tim has developed extensive industry knowledge by working to support the needs of specialty contractors at each and every business level. Tim’s diverse industry background has given him exposure to a wide variety civil construction projects, ranging from the simplest residential applications to the most complex commercial and industrial projects. Coupled with a highly skilled and educated team, Tim focuses on providing the highest quality products and solutions to Intech Anchoring’s customers in order to consistently exceed expectations.