A Resistance Pier – or also known as a Push Pier is a type of foundation repair system that consists of hydraulically pushed steel pipe pier segments. It is designed to restore and stabilize home foundations, as well as commercial and industrial structures that have experienced settlement due to various soil-related issues.

Foundation settlement and movement can occur due to factors such as building on expansive clay, compressible or improperly compacted fill soils, or inadequate maintenance around foundations. These settlement issues can significantly impact the value and safety of structures, necessitating a cost-effective solution.

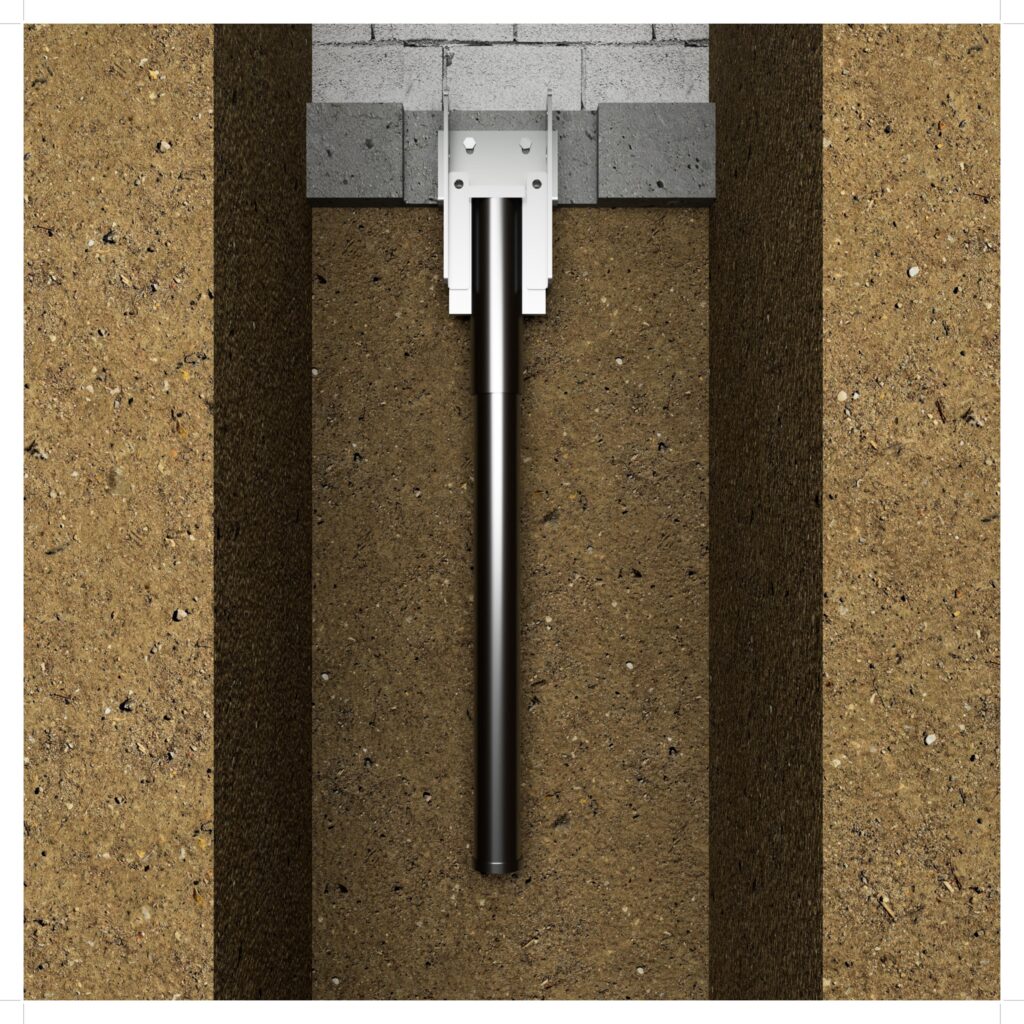

Push Piers are utilized to address these foundation problems by providing support and stabilization. The process involves driving the steel pipe pier segments deep into the ground using hydraulic force. This allows the piers to reach stable soil layers or bedrock beneath the problematic soils. By transferring the weight of the structure onto the piers and the stable soil or bedrock, the settlement is halted or reversed, restoring the foundation’s integrity.

Push Piers offer several advantages as a foundation repair solution. They are cost-effective, providing an efficient and long-lasting remedy for foundation settlement issues. The installation process does not require extensive excavation or disruptive procedures, making it a relatively non-invasive solution. Additionally, the use of hydraulic force allows for precise control during installation, ensuring accurate pier placement and optimal load-bearing capacity.

The resistance push pile system is a highly effective foundation repair solution that utilizes the weight of the structure as its reaction system to drive or push pipe pier sections into the soil. With proper installation, a resistance pier system can prevent settlement, stabilize structures, and even restore settled buildings to their original positions. In many cases, this process can also address structural defects such as cracks and deformities caused by the settlement.

Resistance piers are chosen based on load requirements, as well as soil and structural conditions, ensuring that they are engineered to provide the optimal capacity for each specific project. This ensures a cost-effective solution that meets the unique needs of the structure.

By using the weight of the structure as a reaction system, resistance push piers are able to provide exceptional stability and prevent further settlement. The piers are driven or pushed into the soil, creating a solid foundation that supports the structure and minimizes the risk of future settlement. This process can effectively close structural defects, restoring the integrity and appearance of the building.

Tim is the President of Intech Anchoring and has 25 years of experience in the Civil Engineering and Geostructural Industry. Tim has developed extensive industry knowledge by working to support the needs of specialty contractors at each and every business level. Tim’s diverse industry background has given him exposure to a wide variety civil construction projects, ranging from the simplest residential applications to the most complex commercial and industrial projects. Coupled with a highly skilled and educated team, Tim focuses on providing the highest quality products and solutions to Intech Anchoring’s customers in order to consistently exceed expectations.