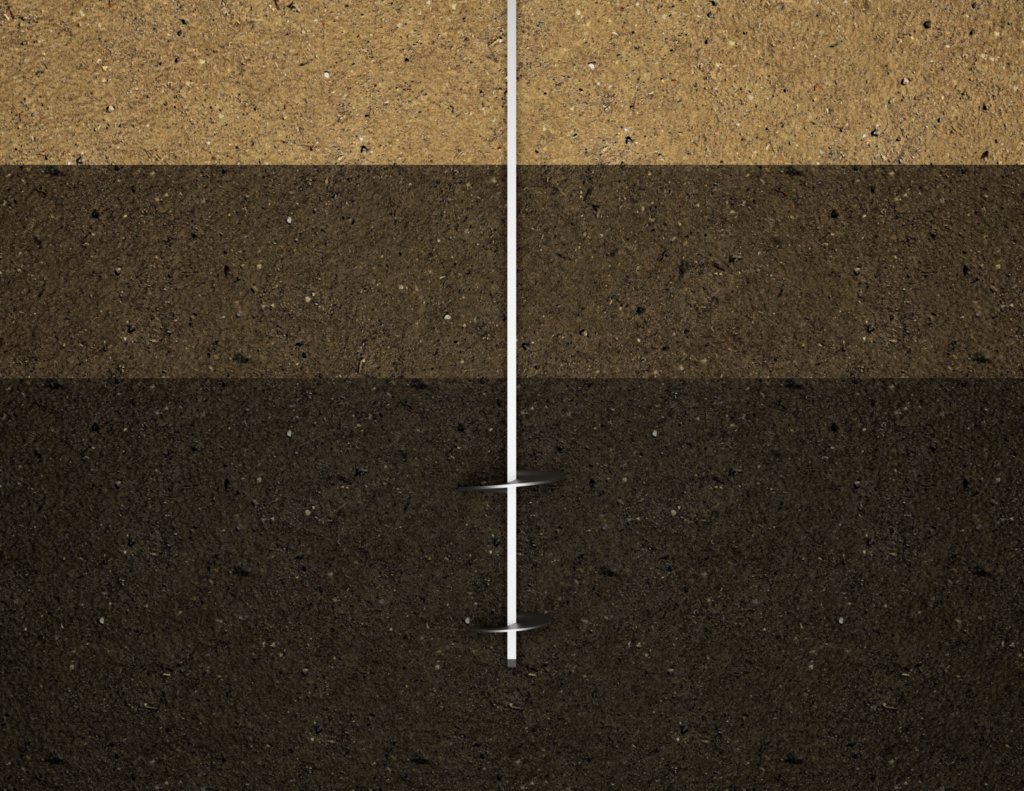

We’ll connect you with the right Helical Pier product line – perfect for a wide range of commercial, industrial, institutional and residential applications—from residential homes and commercial and industrial structures to earth shoring walls, communication towers, and bridges.

When it comes to Earth Anchoring – we only offer top-tier product lines for a diverse group of deep foundation solutions and offering a wide variety of pile sizes.

Plus, we only provide helicals that are ISO 9000 certified and building code approved.

Each project manager is with you from your project’s design, planning and execution – while recommending the most efficient and accurate product – all vetted with The Intech Commitment.

Our recommendations are tailored to meet the specific requirements of your project, whether it’s for a residential, commercial, or industrial application. With our years of expertise and variety of experience, you can trust us to provide you with the best deep foundation system for your needs.

Intech Anchoring Systems offers a wide range of helical piles and anchoring solutions that are designed to provide superior performance, durability, and ease of installation. When you partner with us, traditionally educated and experienced engineers will guide you to the right helical pile solution that’s most ideal for your unique project.

Our partnership with IDEAL DEEP FOUNDATION SYSTEMS allows us to supply all helical projects with a regional family-owned and operated manufacturer and distributor of American-made deep foundation systems.

When your project requires a helical system, rest assured that by connecting with an experienced project engineer at Intech Anchoring Systems – you are set for a smoothly executed and sturdy build every time.

Connect with us today to learn more about our helical pile solutions and how we can help you achieve your build’s goals. We’re committed to strengthening each other.

We offer continued education and certification programs for geotechnical engineers interested in learning more about helical installation. Our programs cover everything from the basics of helical installation to advanced techniques and strategies for complex projects. With our certification, you will have the knowledge and skills necessary to confidently tackle any helical installation project. Plus, our continued education programs ensure that you stay up-to-date with the latest trends and technologies in the industry. Contact us today to learn more about our certification and education programs and take your career to the next level with Intech Anchoring Systems.

Tim is the President of Intech Anchoring and has 25 years of experience in the Civil Engineering and Geostructural Industry. Tim has developed extensive industry knowledge by working to support the needs of specialty contractors at each and every business level. Tim’s diverse industry background has given him exposure to a wide variety civil construction projects, ranging from the simplest residential applications to the most complex commercial and industrial projects. Coupled with a highly skilled and educated team, Tim focuses on providing the highest quality products and solutions to Intech Anchoring’s customers in order to consistently exceed expectations.