The Grouted Helical Micropile is a system for constructing a grout column around the shaft of a standard Helical Pile Foundation System to increase capacity when the normal helicals won’t achieve the job requirements.

The Grouted Helical Micropile does not require removing spoils from the site. By combining both end-bearing on the helical plates and skin friction along the rough surface of the grout column, the result is a higher capacity pile system.

Developed in 1997 for sites with especially weak surface soils, this patented innovative application of the helical pile integrates Portland cement–based grout to increase the section properties of the shaft.

Grouted Helical Micropiles bring the advantages of the pre-engineered helical pile to higher load applications. Plus, it’s able to provide an additional 50% to 100% capacity when compared to an un-grouted helical pier in the same soil conditions.

By “pulling down” a flowable, expansive grout as the foundation is screwed into the soil, these micropiles create a deep foundation with both a friction-bearing central shaft and end-bearing helical plates in competent substrata.

Helical Foundations like these install quickly in any weather condition. A hydraulically powered torque motor mounts to standard construction equipment such as a digger-derrick truck, line truck, rubber tired backhoe, track-hoe excavator, or front-end skid-steer loader. Continuous torque and crowd are applied to advance the Grouted Helical Micropile into the soil for a sturdy build.

This deep foundation product comes with the advantages of increased capacity and corrosion resistance for long-term performance. The installation process itself actually enables grout to be pulled down around the helix as it is screwed into the soil. This speeds up the overall project and allows for greater strength.

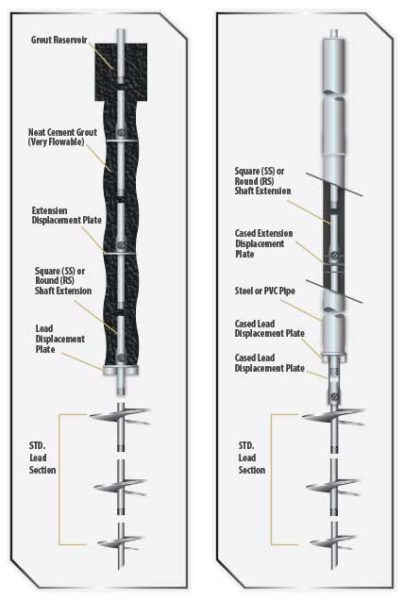

The Grouted Helical Micropile Systems are used to form a grout column around the shaft of a standard helical anchor/pile. The installation process can employ grout only or grout in combination with either steel or PVC casing. To start, a helical anchor/pile drives into the soil by applying torque to the shaft. The helical bearing plates require significant force or torque to advance the helical pile into the soil.

After the lead section containing helical plates penetrates the soil, a lead displacement plate and extension are placed onto the shaft. Torque is again applied on the assembly to advance the helical plates, which pulls the displacement plate downward, forcing soil outward and creating a cylindrical void around the shaft.

From a reservoir at the surface, a flowable grout immediately fills this void surrounding the shaft. Additional extensions and displacement plates are added until the helical bearing plates reach the minimum depth required or competent load-bearing soil. This displacement pile system does not require removing spoils from the site.

You can always count on us to deliver high-quality deep foundation products and solutions, but our professional assistance does not stop there. The most significant factor that separates us from the competition is our team and their experience. We are able to provide industry-leading support thanks to our staff of engineers and experts. They work every day to deliver the products your projects need. We are not just here to sell and rent our products; Intech Anchoring is here to help you succeed.

We are equipped for on-time delivery with ample inventory. Our team provides product and installation training geared for your unique projects. You can take advantage of our expertise with on-site assistance. Our team members will be there to ensure that everything is coordinated correctly and according to engineering specifications. We can even assist in field certifications for your employees. Intech Anchoring is prepared to be your partner in success with all of these services and a library of the best products available on the market today.

Tim is the President of Intech Anchoring and has 25 years of experience in the Civil Engineering and Geostructural Industry. Tim has developed extensive industry knowledge by working to support the needs of specialty contractors at each and every business level. Tim’s diverse industry background has given him exposure to a wide variety civil construction projects, ranging from the simplest residential applications to the most complex commercial and industrial projects. Coupled with a highly skilled and educated team, Tim focuses on providing the highest quality products and solutions to Intech Anchoring’s customers in order to consistently exceed expectations.