Hydravent® is an innovative and cost-effective ventilation system for naturally occurring gases such as methane, radon, and soil gases.

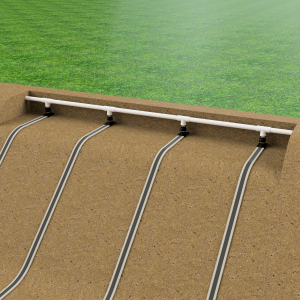

Hydravent is a series of collector lines, systematically spaced, that are connected to vents. It acts as an absorption material beneath liners and vents gases in a controlled, efficient, and safe manner. By using components of the proven Hydraway drainage system, this venting system realizes unparalleled strength,

an industry-leading in-flow rate, and a history of long life. Using Hydravent as a flow path for gases prevents damage caused by these gases, such as lifting or tearing of a liner beneath a water retention pond.

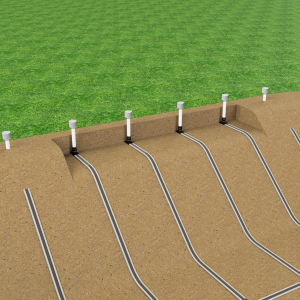

Hydravent is rolled out in a pattern and is covered by a liner. It’s designed with no memory so it easily keeps its shape while the liner is installed. Taking advantage of gravity and slope, Hydravent follows the contours of the area being vented, while the collector lines are orientated in the direction that offers a path of least resistance to the high point. The system is usually spaced at 15-20 foot intervals, creating a grid for collection and removal of gases. Hydravent comes in widths of 6 and 12 inches, with a standard length of 150 feet, though it can be customized in a variety of lengths and widths upon request. And because every project is unique, our engineering team provides consulting and layout designs to ensure the most efficient ventilation of gases.

This system design is used when individual vents are not desirable, aesthetically pleasing, or prevented by local codes. A manifold is usually constructed around the perimeter and PVC/Sch. 40 pipe is used to transport gas.

This system design is used to vent collected gases to the atmosphere, while protecting the system from the elements. They are connected at the highest point of the collector lines. This system is compatible with PVC/Sch. 40 pipe.

Hydravent stands as a reliable and innovative solution for the safe and efficient management of naturally occurring gases. With its unique design, unparalleled strength, industry-leading in-flow rates, and cost-effectiveness, Hydravent is the go-to ventilation system for various applications.

Contact us today to learn more about how Hydravent can meet your specific gas management needs. Our team of experts is ready to assist you in implementing this cutting-edge ventilation system, ensuring a controlled, efficient, and safe environment for your projects. Trust Hydravent for superior gas management and peace of mind.

Project Name – Airport methane venting

Location – Newark, NJ

Industry / Sector – Transportation

Project Summary – Hydravent was used to vent methane gas buildup in walkway tunnel.

Product Type – Hydravent

Project Challenges – Design of venting system that would channel methane gases.

It was determined that methane gas was present in the new walkway tunnel. The specifying engineering firm out of New York City chose Hydravent to mitigate the methane from the tunnel after extensive testing on this high profile project.

As a material supplier, we worked closely with the specifying engineer to provide data and certifications. Intech Anchoring also assisted in the development of customized fittings for the specific use case on this project.

Hydravent Venting System, including the customized fittings, was chosen due to the extremely high in-flow rate of methane gases. With Hydravent’s compressive strength, the system was tested to failure and proved an excellent option for this project.

Hydravent performed as expected and continues to perform exceptionally well. The customized fittings worked as designed. Hydravent was installed with 25-foot spacing on the outside of the tunnel walls that went up and over the wall. The project was completed on time with the expected results.

Tim is the President of Intech Anchoring and has 25 years of experience in the Civil Engineering and Geostructural Industry. Tim has developed extensive industry knowledge by working to support the needs of specialty contractors at each and every business level. Tim’s diverse industry background has given him exposure to a wide variety civil construction projects, ranging from the simplest residential applications to the most complex commercial and industrial projects. Coupled with a highly skilled and educated team, Tim focuses on providing the highest quality products and solutions to Intech Anchoring’s customers in order to consistently exceed expectations.